Technology Brief

Smart mine has become the inevitable path for the high quality and sustainable development of traditional mining enterprises. As the “national team” of the Chinese nonferrous mining and metallurgy industry, ENFI can help realize systemic digitalization of conventional operations and build smart, highly automated mines that are safe, environmentally friendly, and efficient. With its own mining information model (MIM), ENFI can provide “one-stop” technical services across the entire project life cycle: from planning, design, construction/installation, operation and maintenance, right through pit closure, supported by a number of core expertise technologies such as transportation & lifting, filling & ventilation, intelligent mineral processing, fused control and mine integration control, etc.

SERVICE CALL+86 13521339794

SERVICE CALL+86 13521339794 Price Inquiry

Price Inquiry

Online Remarks

Online Remarks

Process Description

Automatic mining technology

Proper mining methodology is selected based on the occurrence conditions of ore body, and automatic mining operation in stope is realized by employing automatic mining system with optimized secondary development and mining process.

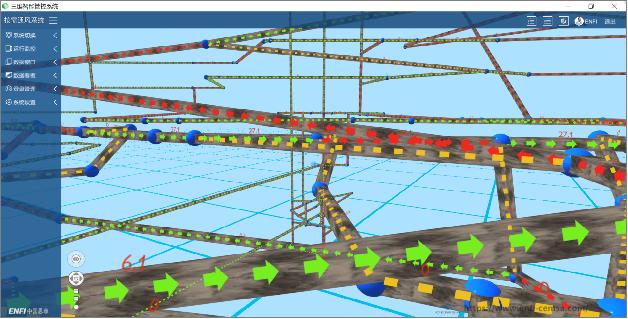

Unmanned track haulage system

Based on automated operation and an integrated control of the entire transport process, the unmanned track haulage system is intrinsically safe as no site human presence is necessary, and with augmented data-driven control, transportation efficiency has also been greatly improved.

Automatic hoist control system

By applying full digital automatic control technology, the operation of the hoist can be controlled by the operator from the control room on the ground.

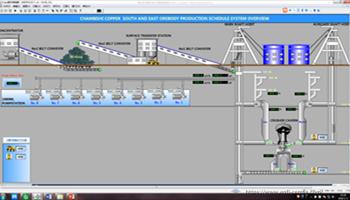

Fused control and intelligent mineral processing system

An in-depth fusion of smart distribution and control, the system solves the problem of having numerous, isolated and badly organized power and control systems in one mine, a problem which is common in China. Also the fused distribution and control system can provide a large pool of data coming from the field for mine operation management, and thus enable data-driven decision making.

Automatic filling control system

Relying on process design and intelligent analysis, automatic filling control is realized with real-time optimization and adjustment of various key parameters including liquid level, flow rate and metering. With the application of industrial control system and APP mobile terminal, “one-key” intelligent filling is completed.

Intelligent drainage and pump station unattended system

With in-depth integration of video monitor, intelligent control and communication system, remote control of the power supply equipment and pump station is achieved via remote monitoring from surface central control room on the status of underground unattended substation and pumps, power and network operation.

Ventilation on demand system

With advanced and reliable network fusion and control, the system can bring remarkable economic benefits by saving ventilation power through a number of techniques: automated VSD control for all fans, unattended fan stations, automated adjustment of ventilation structures, real-time monitoring, and on-demand ventilation for personnel, equipment, and work fronts.

Intelligent mineral processing and optimized control system

In intelligent mineral processing, basic automation, computer vision, soft measurement, advanced control and other technologies are employed to optimize the process control and to achieve intelligent crushing control system, intelligent grinding control system, intelligent flotation control system, intelligent dewatering control system thus to ensure stable and efficient operation of production, improve product quality and recovery rate, reduce labor force, promote the level of equipment automation and economic benefits.

Integrated information platform for smart mine

With big data services and 3D visualization technology, digital management can be realized on the information of automatic mining, automatic transport&hoist, and unattended fixed facilities. A remote diagnosis service and cloud platform is established along with a remote data storage & analysis platform and a remote technical service platform, An intelligent mine ecosystem is built to provide life-cycle services for the whole mining industry chain.

Required Equipment

Intelligent Tailings Filling Package Equipment

Electric Control System of Mine Hoist

Unmanned Electric Locomotive

Unloading Bottom Dump Car and Unloading Station

Automatic intelligent ore sorting machine

Excavators

Related Cases

2

3