Technology Brief

ENFI owns a variety of copper smelting processes covering flash converting, top-blowing, bottom-blowing, side-blowing, pressure leaching, heap leaching, bioleaching, roasting leaching, and has undertaken the design of world largest top-blowing, flash converting and oxygen bottom-blowing copper smelting production lines with maximum concentrate throughput exceeding 1800kt/a for single set. We have rich engineering experience in the fields of copper sulfide, copper oxide, complex copper-nickel mixed ore, complex copper-cobalt oxide, complex copper-cobalt sulfide, and comprehensive recovery of secondary copper resources.

SERVICE CALL+86 13521339794

SERVICE CALL+86 13521339794 Price Inquiry

Price Inquiry

Online Remarks

Online Remarks

Process Description

Bottom-blowing copper smelting process

Oxygen-enriched air is blown into the melt at high velocity through the bottom lance of the horizontal rotary furnace, to engage in chemical reaction with the concentrate.

Oxygen bottom-blowing converting process (BCC)

Bottom-blowing horizontal furnace is adopted. Oxygen-enriched air is blown into the furnace via the lance at the bottom of the furnace to engage in the reaction with copper matte to produce blister copper.

Enriched oxygen side-blowing bath smelting process

Side-blowing smelting process

Horizontal fixed furnace is adopted. The concentrate is directly fed into the furnace via the feed port at the furnace top, while oxygen and air is injected via the injector on the furnace side to engage in the chemical reaction.

Multi-lance top-blowing converting process

Fixed horizontal furnace is adopted. The oxygen-enriched air is injected via multiple top-blowing lances to produce qualified blister copper through reaction.

Recovery of secondary copper resources

Side-submerged combustion smelting process (SSC)

An oxygen-enriched side-submerged furnace is used to intensively smelt the low-grade miscellaneous copper, circuit boards, copper-containing slime, copper-containing off-gas, etc. to produce blister copper containing valuable metals.

Copper sulfide hydrometallurgical process

Pressure leaching process

The valuable metals such as copper and cobalt in the sulfide are leached into the solution under the conditions of pressure, high temperature and oxygen injection.

Copper electrowining process

We own three-phase crud extraction and separation process, oil removal process for electrolyte, acid mist suppression and absorption process for electrowinning, and design capability for large-scale copper extraction box and extraction process optimization.

Copper anode slime processing process

Combined process of oxygen incline-blowing rotary converter

Pressure leaching is adopted to remove copper and tellurium, while incline-blowing rotary converter is used to directly output anode plates containing gold and silver.

Required Equipment

Super-large side-blowing converting (SSC) technical equipment and control system

WHB of Smelting

Complete Set of VPSA Equipment

SKS furnace process equipment and control system

Oxygen lance

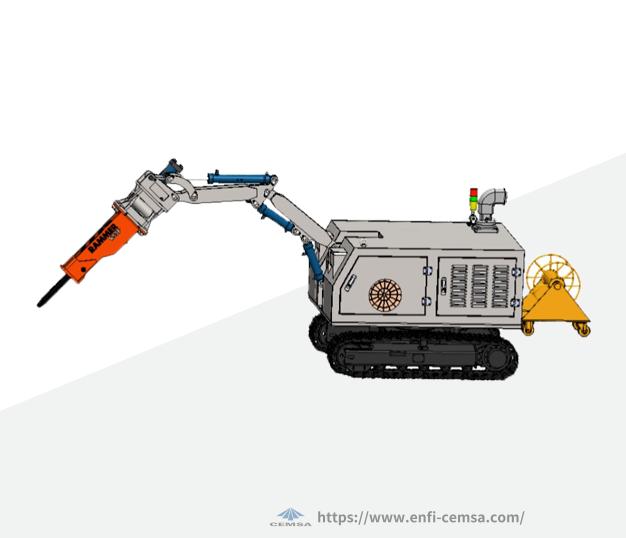

Multi-function mechanical arm in front of the furnace

Related Cases

2

3