Product Brief

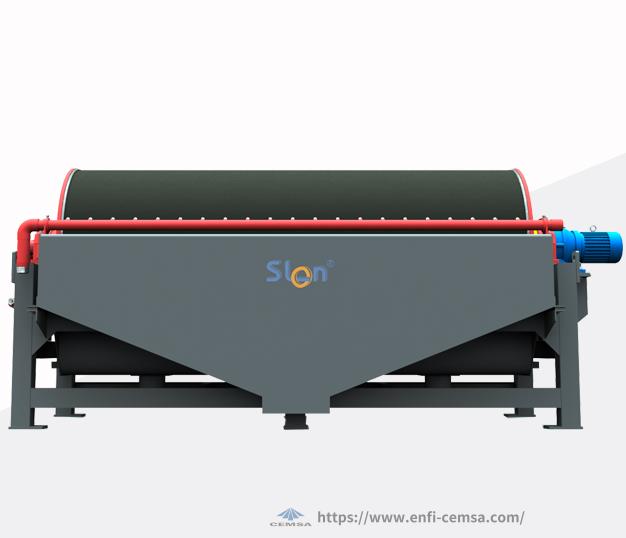

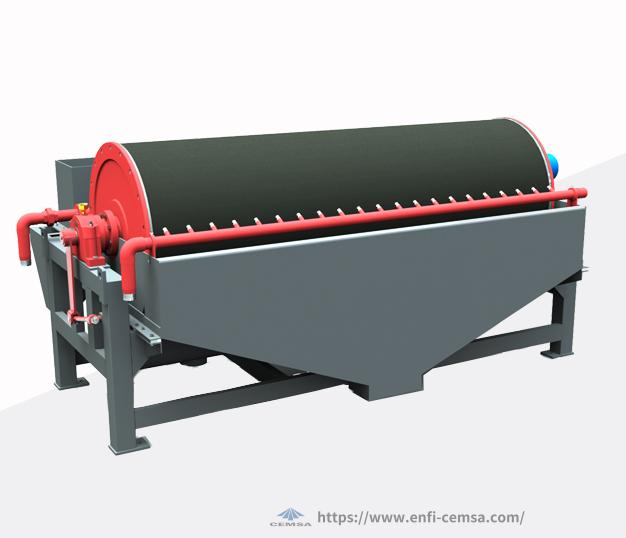

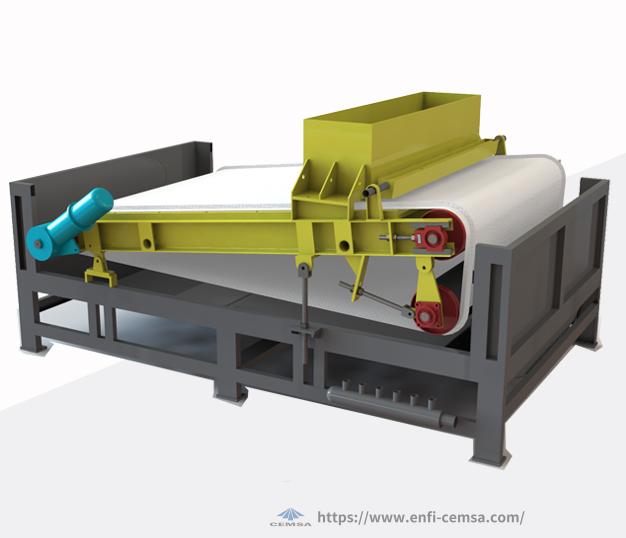

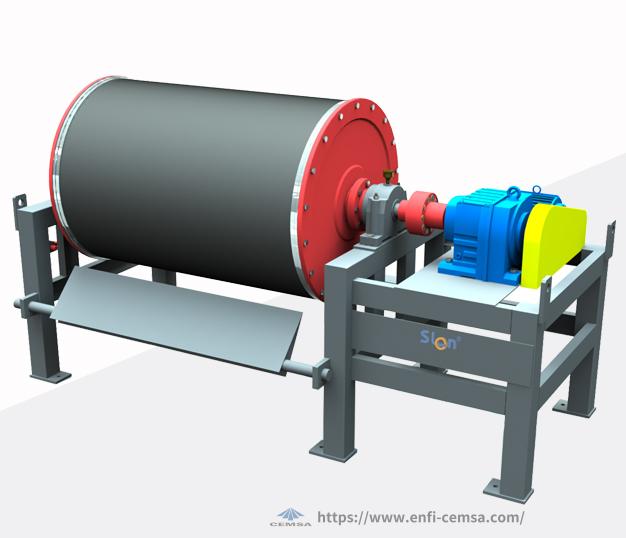

Wet Drum Magnetic Separator

Wet drum magnetic separator is widely used in mines and coal separating factories to separate the wet fine magnetic substances or remove the magnetic substances from the non-magnetic materials. It‘’s suitable for processing magnetite,pyrrhotite, magnetite, titanium magnetite, calcined ore and other materials, as well as the iron removal and purification of feldspar, quartz sand, kaolin and other non-metallic minerals.

Specification & Series:SCTB/SCTS/SCTN

Specification & Series:SCTB/SCTS/SCTN

Processing Capacity:0.05~240t/h

Processing Capacity:0.05~240t/h

SERVICE CALL+86 13521339794

SERVICE CALL+86 13521339794

enfi.cemsa@gmail.com

enfi.cemsa@gmail.com

Advantages & Features

Reliable magnetic material, made of high magnetic remanence and high coercivity magnetic materials, which has very good anti-demagnetization ability, and the demagnetization does not exceed 5% in eight years;

Reliable magnetic material, made of high magnetic remanence and high coercivity magnetic materials, which has very good anti-demagnetization ability, and the demagnetization does not exceed 5% in eight years;

Slon applied a unique and reliable fixing scheme to ensure the magnetic group will never fall off and be damaged;

Slon applied a unique and reliable fixing scheme to ensure the magnetic group will never fall off and be damaged;

Duckbill shape flushing hose, has strong adaptability to water quality and large water pressure, can effectively saving water of 50%;

Duckbill shape flushing hose, has strong adaptability to water quality and large water pressure, can effectively saving water of 50%;

Optional protection material, such as:wear-resistant rubber, stainless steel and wear-resistant ceramics.

Optional protection material, such as:wear-resistant rubber, stainless steel and wear-resistant ceramics.

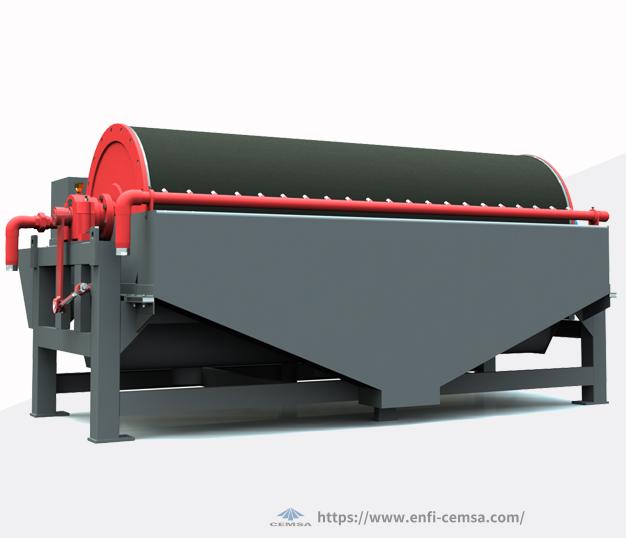

Working Principle

This machine uses magnetic force produced by permanent magnet magnetic department, will be adsorbed on the cylinder surface strong magnetic minerals in the pulp, the magnetic field and scattered under the action of water flow, the implementation of the magnetic material and the separation of magnetic materials, magnetic minerals with cylinder rotate to concentrate end is concentrate rinse water washing to collecting tank, rather than a magnetic material from the tailings discharge mouth, complete the sorting operation.

Technical Parameters

| Type | Diameter | Length | Speed | Feed density | Ore throughput | Slurry throughput | Power | Weight |

|---|---|---|---|---|---|---|---|---|

| mm | mm | r/min | % | t/h | m3/h | Kw | t | |

| SCT-44 (Lab) | 400 | 400 | 20~50 | 20~30 | 0.05~0.5 | 0.15~2.5 | 0.55 | 0.4 |

| SCTB/S/N-66 | 600 | 600 | 36 | 20~30 | 5~10 | 15~20 | 1.5 | 0.8 |

| SCTB/S/N-69 | 600 | 900 | 36 | 20~30 | 8~15 | 18~35 | 1.5 | 1 |

| SCTB/S/N-612 | 600 | 1200 | 36 | 20~30 | 10~20 | 35~55 | 2.2 | 1.25 |

| SCTB/S/N-618 | 600 | 1800 | 36 | 20~30 | 15~30 | 40~65 | 3 | 1.8 |

| SCTB/S/N-712 | 700 | 1200 | 36 | 20~30 | 15~25 | 40~65 | 3 | 1.8 |

| SCTB/S/N-718 | 700 | 1800 | 36 | 20~30 | 18~35 | 60~100 | 3 | 2.2 |

| SCTB/S/N-918 | 900 | 1800 | 26 | 25~35 | 20~45 | 70~120 | 4 | 2.7 |

| SCTB/S/N-924 | 900 | 2400 | 26 | 25~35 | 30~55 | 120~190 | 5.5 | 3.6 |

| SCTB/S/N-1018 | 1050 | 1800 | 21 | 25~35 | 45~60 | 110~160 | 4 | 3.4 |

| SCTB/S/N-1021 | 1050 | 2100 | 21 | 25~35 | 50~70 | 140~200 | 5.5 | 4.1 |

| SCTB/S/N-1024 | 1050 | 2400 | 21 | 25~35 | 55~80 | 170~230 | 5.5 | 4.8 |

| SCTB/S/N-1030 | 1050 | 3000 | 21 | 25~35 | 65~100 | 240~400 | 7.5 | 6.2 |

| SCTB/S/N-1218 | 1200 | 1800 | 17 | 25~35 | 60~75 | 160~250 | 4 | 4.7 |

| SCTB/S/N-1224 | 1200 | 2400 | 17 | 25~35 | 70~110 | 220~380 | 5.5 | 5.7 |

| SCTB/S/N-1230 | 1200 | 3000 | 17 | 25~35 | 80~140 | 260~460 | 7.5 | 6.7 |

| SCTB/S/N-1236 | 1200 | 3600 | 17 | 25~35 | 100~160 | 280~540 | 7.5 | 7.7 |

| SCTB/S/N-1245 | 1200 | 4500 | 17 | 25~35 | 130~190 | 360~640 | 15 | 11 |

| SCTB/S/N-1530 | 1500 | 3000 | 15 | 25~40 | 100-180 | 290-480 | 11 | 10 |

| SCTB/S/N-1545 | 1500 | 4500 | 15 | 25~40 | 180-240 | 400-650 | 18.5 | 15 |

The Application Achievements

Related Recommendations