Product Brief

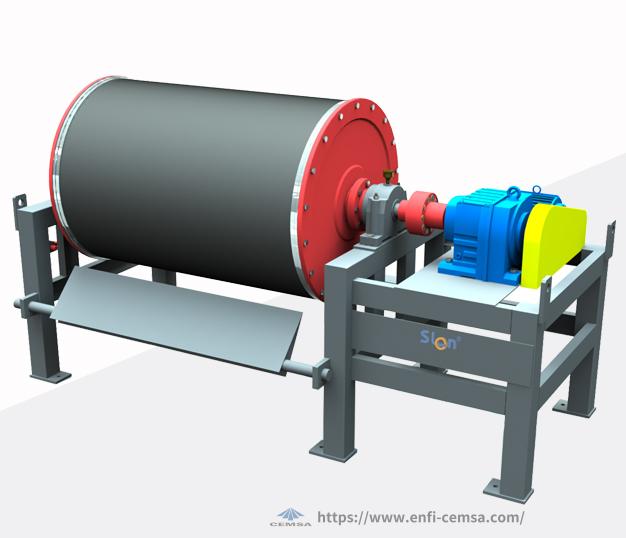

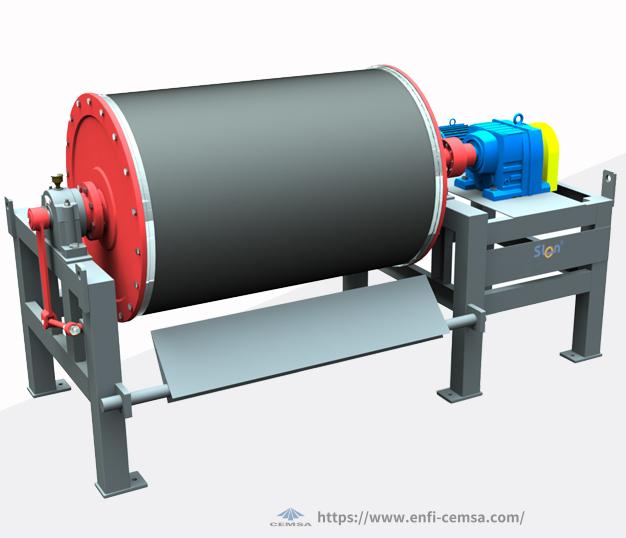

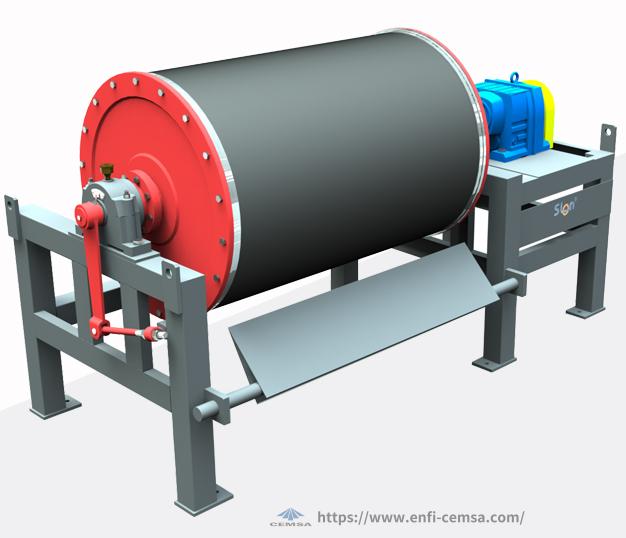

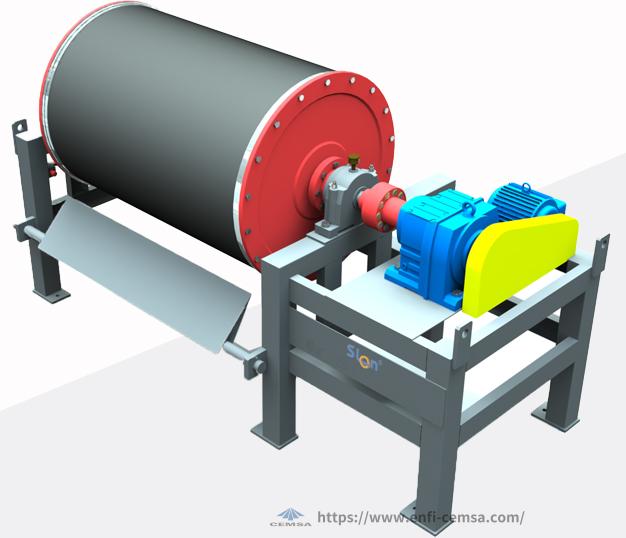

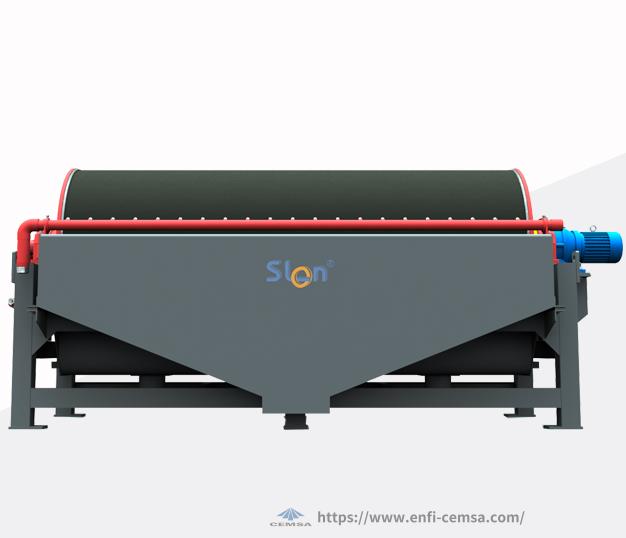

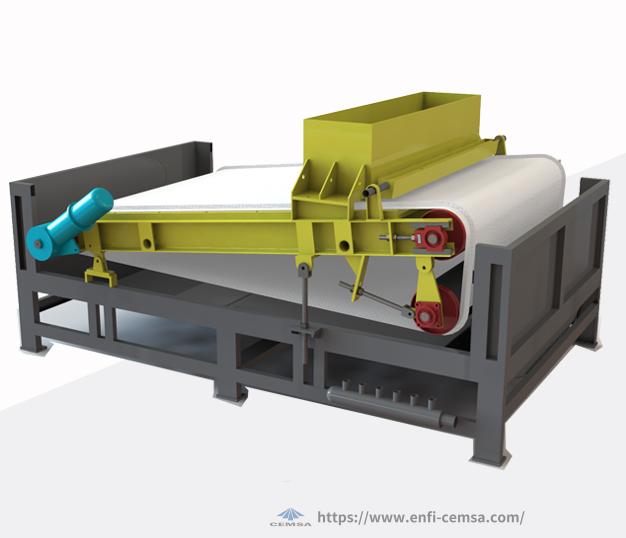

Pulley Separator

Pulley Magnetic Separator is widely used as head pulleys in belt conveyors for continuous automatic removal iron materials from a variety of materials.

It is suitable for waste recovery, mining, recycling application, cement, coal handing plant, refractory for remove iron material or recovery iron material.

It is suitable for waste recovery, mining, recycling application, cement, coal handing plant, refractory for remove iron material or recovery iron material.

Specification & Series:SGTD-0506,SGTD-0507,SGTD-0509,SGTD-0607 and so on.

Specification & Series:SGTD-0506,SGTD-0507,SGTD-0509,SGTD-0607 and so on.

SERVICE CALL+86 13521339794

SERVICE CALL+86 13521339794

enfi.cemsa@gmail.com

enfi.cemsa@gmail.com

Advantages & Features

High magnetic induction intensity;

High magnetic induction intensity;

Deep magnetic field action;

Deep magnetic field action;

Stable and reliable magnetic system.

Stable and reliable magnetic system.

Working Principle

Ferrous materials pass through the pulley’s magnetic field, and the iron is attracted and held to the belt until it reaches the underside, passes out of the magnetic field, and is separately discharged. The cleaned, nonmagnetic material is discharged over the pulley in a normal trajectory. A splitter assembly is required to separate segmented material fractions. An adjustable splitter will permit separation fine tuning and provide optimum separation performance for your application.

Technical Parameters

| Parameters | Diameter | Length | Belt width | Ore throughput | Feed size | Weight |

|---|---|---|---|---|---|---|

| mm | mm | mm | t/h | mm | t | |

| SGTD-0506 | 500 | 600 | 500 | 20~40 | 10~40 | 0.7 |

| SGTD-0507 | 500 | 750 | 650 | 30~50 | 10~40 | 0.8 |

| SGTD-0509 | 500 | 950 | 800 | 35~55 | 10~40 | 1 |

| SGTD-0607 | 600 | 750 | 650 | 35~55 | 10~150 | 1 |

| SGTD-0609 | 600 | 950 | 800 | 50~60 | 10~150 | 1.4 |

| SGTD-0612 | 600 | 1200 | 1000 | 80~100 | 10~150 | 1.8 |

| SGTD-0809 | 800 | 950 | 800 | 50~80 | 10~200 | 2.2 |

| SGTD-0812 | 800 | 1200 | 1000 | 65~100 | 10~200 | 2.5 |

| SGTD-0814 | 800 | 1400 | 1200 | 80~120 | 10~200 | 2.7 |

| SGTD-0816 | 800 | 1600 | 1400 | 80~120 | 10~200 | 4.35 |

| SGTD-1012 | 1000 | 1200 | 1000 | 70~120 | 10~300 | 4.2 |

| SGTD-1014 | 1000 | 1400 | 1200 | 80~150 | 10~300 | 4.8 |

| SGTD-1016 | 1000 | 1600 | 1400 | 150~200 | 10~300 | 5.4 |

| SGTD-1214 | 1200 | 1400 | 1200 | 100~200 | ≤350 | 5.45 |

| SGTD-1216 | 1200 | 1600 | 1400 | 150~250 | ≤350 | 6.8 |

| SGTD-1416 | 1400 | 1600 | 1400 | 200~350 | ≤350 | 10 |

Related Recommendations