Product Brief

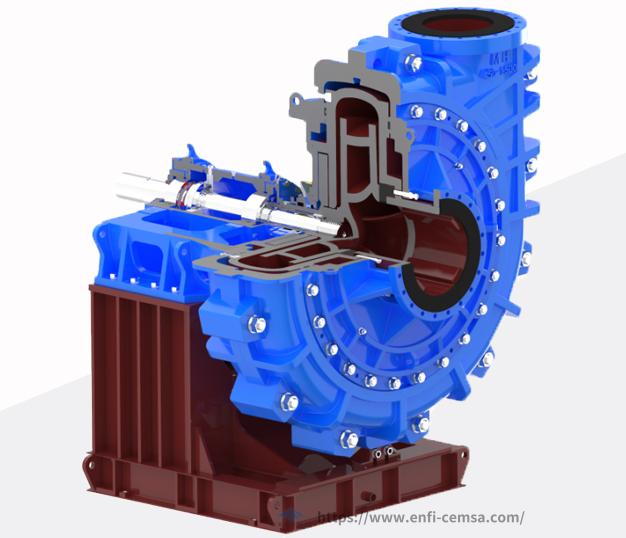

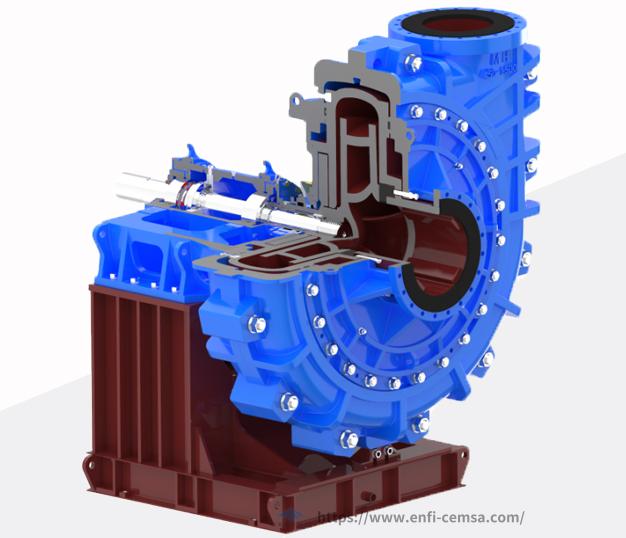

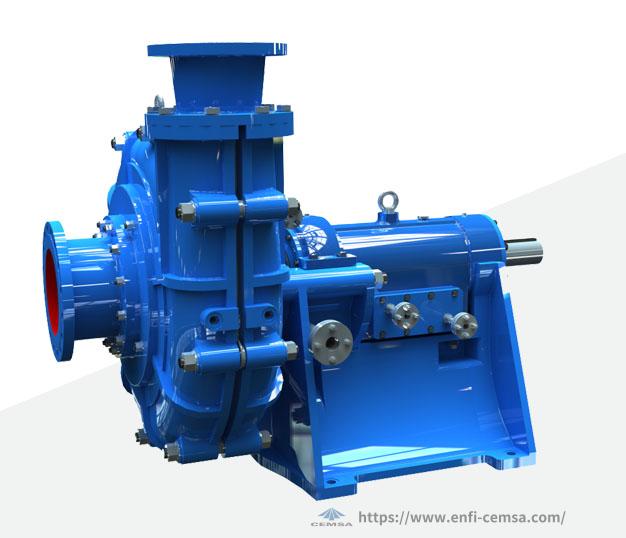

MH Heavy duty slurry pump

MH heavy-duty slurry pump is applicable to the transportation of abrasive slurry containing high concentration and large-size particles in mining and metallurgical industry, such as wet crushing, semi self grinding discharge, ball mill discharge, rod mill discharge, tailings transportation, dredging, ore sand, coal mine and other heavy media.

SERVICE CALL+86 13521339794

SERVICE CALL+86 13521339794

enfi.cemsa@gmail.com

enfi.cemsa@gmail.com

Advantages & Features

The overall design adopts double shell and overweight load bearing components, which makes the operation safe and reliable;

The overall design adopts double shell and overweight load bearing components, which makes the operation safe and reliable;

High efficiency impeller with low speed and large diameter maximizes the service life of the pump;

High efficiency impeller with low speed and large diameter maximizes the service life of the pump;

The wide runner design ensures that the slurry is unobstructed in the runner;

The wide runner design ensures that the slurry is unobstructed in the runner;

The adjustable wear ring structure can prolong the service life of the impeller and the front wear plate, and maintain the pump efficient operation;

The adjustable wear ring structure can prolong the service life of the impeller and the front wear plate, and maintain the pump efficient operation;

The front and rear pump housings are made of nodular cast iron and connected by through bolts, which is convenient for maintenance;

The front and rear pump housings are made of nodular cast iron and connected by through bolts, which is convenient for maintenance;

The mating surfaces of the front and rear pump casings are fully fitted, and there is no gap in the middle, which is more pressure bearing and safer.

The mating surfaces of the front and rear pump casings are fully fitted, and there is no gap in the middle, which is more pressure bearing and safer.

Working Principle

The service life of the heavy slurry pump in the worst environment is improved through large-size impeller and low speed design, which meet the market demand of larger flow range, higher particle hardness and safer and reliable operation.

Technical Parameters

| Model | Flow(m³/h) | Lift(m) | Rotational speed(r/min) | Efficiency(%) |

|---|---|---|---|---|

| MH300-1000 | 1800 | 90 | 740 | 78 |

| MH350-800 | 2800 | 50 | 740 | 80 |

| MH350-900 | 3800 | 62 | 740 | 82 |

| MH350-1100 | 3500 | 64 | 590 | 84 |

| MH450-1500 | 4800 | 36 | 350 | 86 |

| MH550-1600 | 6000 | 44 | 350 | 86 |

| MH650-1800 | 8500 | 40 | 300 | 88 |

| MH750-2000 | 12000 | 40 | 260 | 88 |

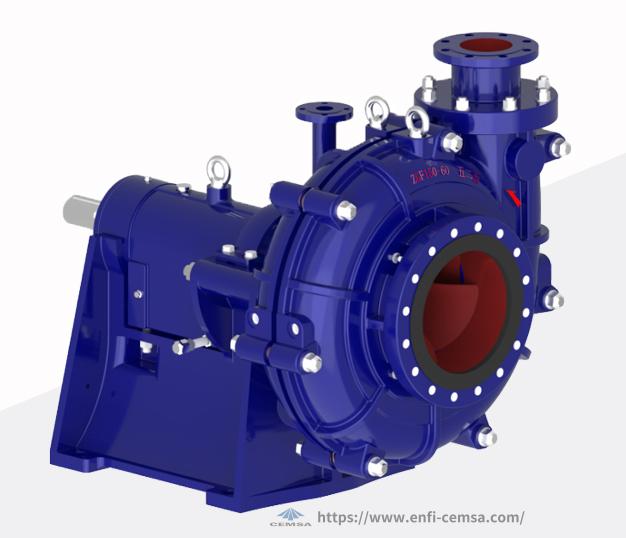

Related Recommendations