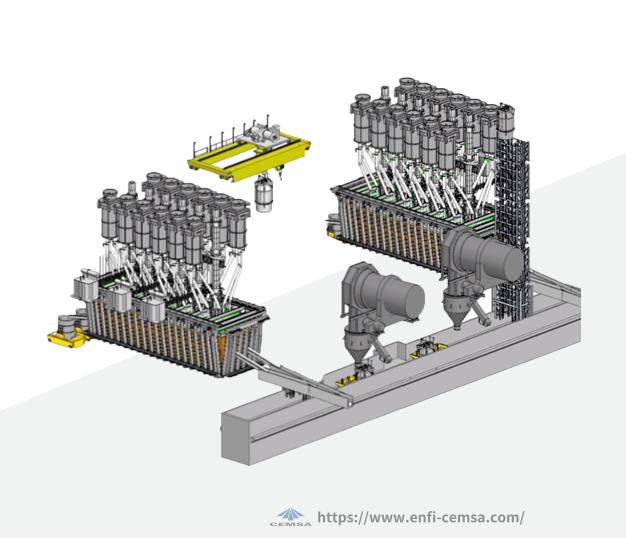

Product Brief

Hot material conveying system

As a product of mechanical-electrical integration system independently developed by ENFI, the hot material conveying system is used to transport 800℃-1000℃ high-temperature calcine in sealed 3D space (from the discharge end of rotary kiln to the bin of EF), reducing heat loss during transport and protecting hot materials from oxidation.

Processing Capacity:Temperature of hot calcine: ≤1000℃; rated conveying capacity: 92t/h; maximum conveying capacity: 136.8t/h;

Processing Capacity:Temperature of hot calcine: ≤1000℃; rated conveying capacity: 92t/h; maximum conveying capacity: 136.8t/h;

Series of effective capacities of double-walled heat-insulated containers:1.4m³,7.5 m³,9 m³,10 m³,16.2 m³,19m³. Application Fields:This system is suitable for conveying hot granular and powdery materials, and applicable to FeNi smelting, calcium carbide industry, and fields with scenarios of conveying hot bulk materials.

Application Fields:This system is suitable for conveying hot granular and powdery materials, and applicable to FeNi smelting, calcium carbide industry, and fields with scenarios of conveying hot bulk materials.

FeNi smelting: it can be used for FeNi production lines of 33MVA, 39MVA, 42MVA/48MVA and 72MVA, such as eight 48MVA FeNi production lines in Lygend FeNi Project and two 72MVA FeNi production lines in Tagaung Taung Nickel Mine Project in Myanmar;

Calcium carbide: it is mainly used to convey hot calcium carbide produced by submerged arc furnace;

Other fields with scenarios of conveying hot bulk materials.

SERVICE CALL+86 13521339794

SERVICE CALL+86 13521339794

enfi.cemsa@gmail.com

enfi.cemsa@gmail.com

Advantages & Features

Long-distance 3D conveyance across space, with a large elevation difference and a conveying range between 20m and 200m;

Long-distance 3D conveyance across space, with a large elevation difference and a conveying range between 20m and 200m;

Less heat loss and good thermal insulation effect: it can convey hot materials at a temperature of up to 1,000℃, and the temperature drops by around 50℃ over 100m;

Less heat loss and good thermal insulation effect: it can convey hot materials at a temperature of up to 1,000℃, and the temperature drops by around 50℃ over 100m;

Eco-friendliness: hot materials are fully sealed during conveyance, and the material unloading procedure is interlocked with ventilation without escape of hot materials and dust;

Eco-friendliness: hot materials are fully sealed during conveyance, and the material unloading procedure is interlocked with ventilation without escape of hot materials and dust;

Intelligent control and operation: processes of weighing, conveying, transfer, selection of bins and feeding are all automatic, and the system is under intelligent control and operation.

Intelligent control and operation: processes of weighing, conveying, transfer, selection of bins and feeding are all automatic, and the system is under intelligent control and operation.

The Application Achievements

Related Recommendations