Product Brief

Feeder

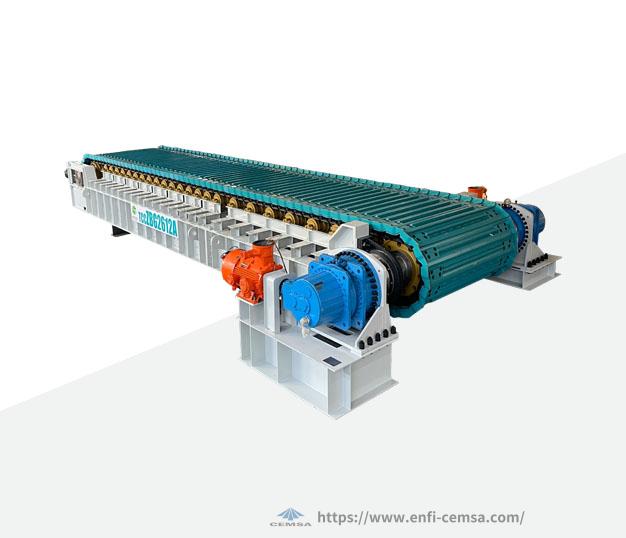

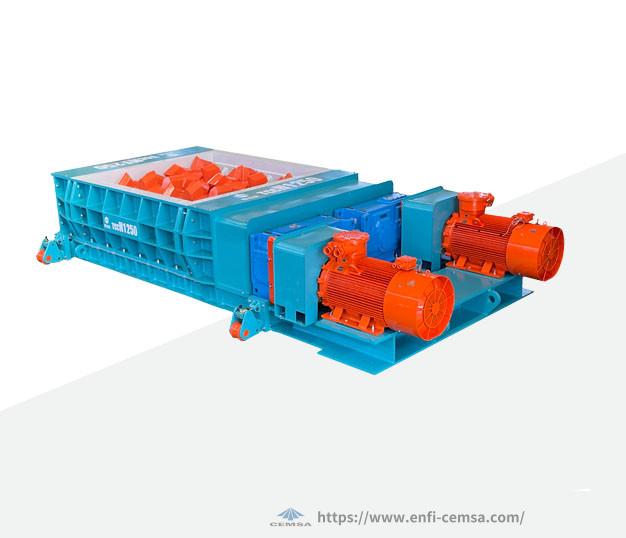

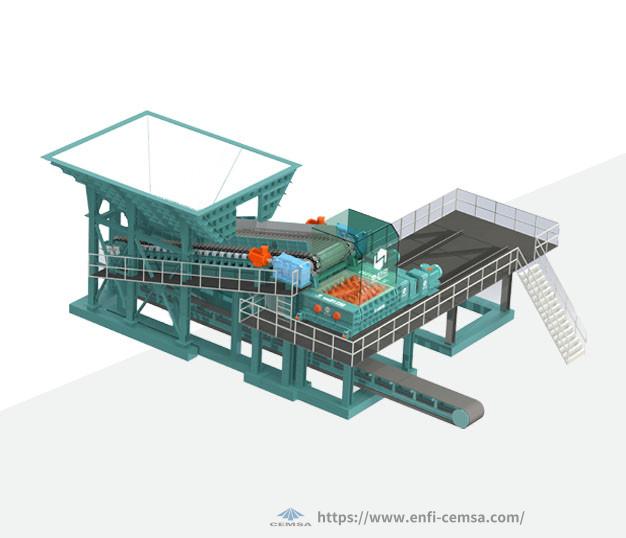

CEMSA offers multiple feeders to meet most customers' needs, TCC, a member of CEMSA, produces heavy duty apron and scraper feeders for primary crushing applications as well as medium duty apron, grizzly and reciprocating feeders for crushed primary or secondary feed.

Specification & Series:TCCAF series, TCCSF series

Specification & Series:TCCAF series, TCCSF series

Processing Capacity:3,000TPH

Processing Capacity:3,000TPH

Application Fields:TCC has accumulated over thirty years of experience in the design and production of feeders, continually improving and optimizing feeder structures to meet industry demands. With a stable and reliable structure, the feeder is easy to install, operate, and maintain, ensuring straightforward operation. The uninterrupted service design is applicable to the conveyance of materials such as iron ore, gold ore, coal, bauxite, limestone, nickel ore, and lithium ore.

Application Fields:TCC has accumulated over thirty years of experience in the design and production of feeders, continually improving and optimizing feeder structures to meet industry demands. With a stable and reliable structure, the feeder is easy to install, operate, and maintain, ensuring straightforward operation. The uninterrupted service design is applicable to the conveyance of materials such as iron ore, gold ore, coal, bauxite, limestone, nickel ore, and lithium ore.

SERVICE CALL+86 13521339794

SERVICE CALL+86 13521339794

enfi.cemsa@gmail.com

enfi.cemsa@gmail.com

Advantages & Features

Main frame construction designed to absorb impact when loading big lumps.

Main frame construction designed to absorb impact when loading big lumps.

Effective take-up system to ensure constant chain tension.

Effective take-up system to ensure constant chain tension.

Available with either an electromechanical or hydraulic drive.

Available with either an electromechanical or hydraulic drive.

Can be installed horizontally or on an incline.

Can be installed horizontally or on an incline.

Aprons (or scrapers) and chains can be accessed from the take-up end of the feeder for inspection and replacement.

Aprons (or scrapers) and chains can be accessed from the take-up end of the feeder for inspection and replacement.

Working Principle

The working principle of a heavy-duty apron feeder involves the motor's power transmitted through a coupling and reducer to drive the sprocket shaft. The sprocket teeth engage with the pins of the chain, causing the chain plates to move in a continuous linear motion. The chain plates are supported by support wheels and guide wheels mounted on the frame. The tensioning device is adjusted to ensure proper engagement between the chain and sprocket, enabling the continuous transportation of materials.

Technical Parameters

| 型号Model | 链板宽度/mm | 中心距/m/ | 给料尺寸/mm/ | 处理能力/t/h | 功率/kw |

|---|---|---|---|---|---|

| ZBG08-L | 800 | 3-10 | ≤400 | ≤210 | 7.5-11 |

| ZBG10-L | 1000 | 3-10 | ≤500 | ≤300 | 11-22 |

| ZBG12-L | 1200 | 4-10 | ≤600 | ≤350 | 11-30 |

| ZBG15-L | 1500 | 6-10 | ≤750 | ≤500 | 15-37 |

| ZBG16-L | 1600 | 6-10 | ≤850 | ≤600 | 30-45 |

| ZBG18-L | 1800 | 6-10 | ≤950 | ≤700 | 37-55 |

| ZBG20-L | 2000 | 6-12 | ≤1000 | ≤900 | 45-75 |

| ZBG22-L | 2200 | 6-12 | ≤1200 | ≤1100 | 45-75 |

| ZBG23-L | 2300 | 6-12 | ≤1500 | ≤1200 | 45-90 |

| ZBG24-L | 2400 | 10-15 | ≤1600 | ≤1300 | (45-90) *2 |

| ZGB26-L | 2600 | 10-15 | ≤1800 | ≤1500 | (55-110)*2 |

The Application Achievements

Related Recommendations