Product Brief

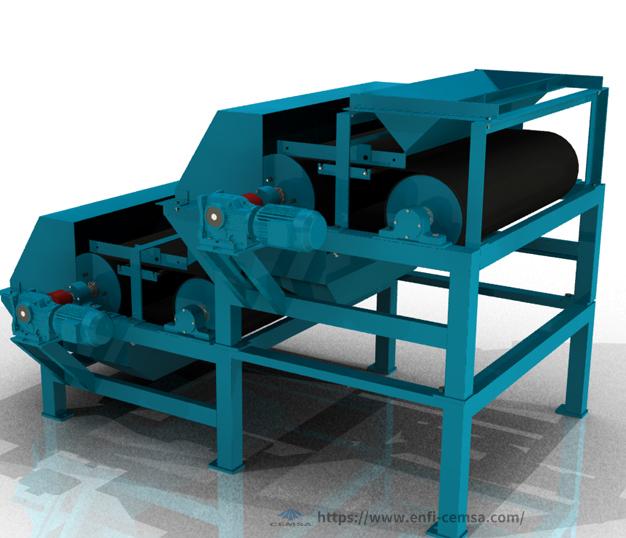

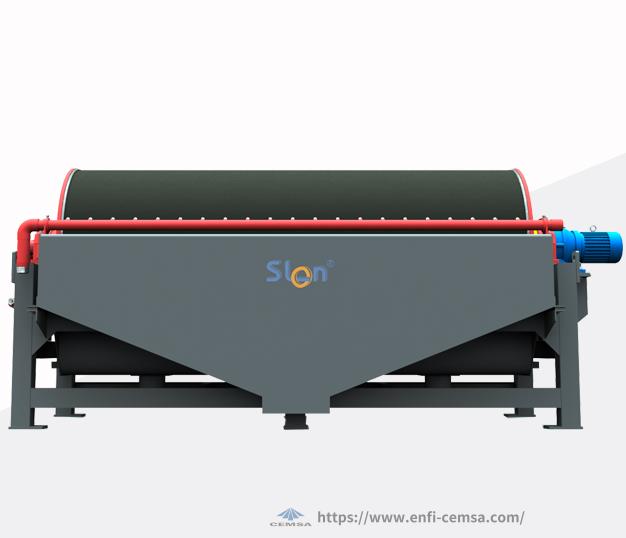

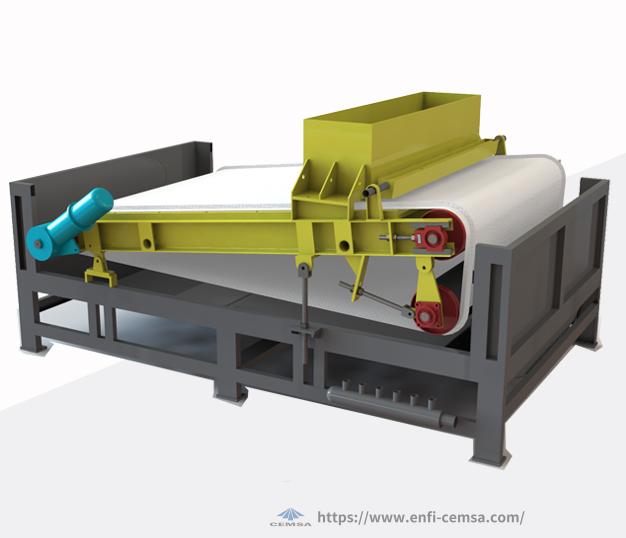

Dry Drum Magnetic Separator

The dry drum magnetic separator suitable for processing hematite, limonite, mirror iron ore, chromite, manganese ore, wolframite and other weak magnetic minerals in the tailing discarding stage; Remove harmful magnetic impurities from different products.

Specification & Series:GTQ0105,GTQ0110,GTQ1510, GTQ1515,GTQ0310 and so on.

Specification & Series:GTQ0105,GTQ0110,GTQ1510, GTQ1515,GTQ0310 and so on.

Processing Capacity:0.4~80t/h

Processing Capacity:0.4~80t/h

SERVICE CALL+86 13521339794

SERVICE CALL+86 13521339794

enfi.cemsa@gmail.com

enfi.cemsa@gmail.com

Advantages & Features

High magnetic field(up to 15000GS);

High magnetic field(up to 15000GS);

The mass and grade of both concentrate and tailings can be controlled through stepless speed regulation of roller and adjustment of the separator.

The mass and grade of both concentrate and tailings can be controlled through stepless speed regulation of roller and adjustment of the separator.

Working Principle

The materials convey into belt by vibrating feeder with uniformly layering, when materials pass through the strength magnetic roller, the magnetic particles are adsorbed to the strength magnetic roller due to the magnetic force, with rotation of the belt, the magnetic particles break away from magnetic filed and fall into mags collect hopper, nonmagnetic materials are discharged over the roller in a normal trajectory., then fall into non-mags collect hopper, the working principle shown as figure 2. The equipment can be configured into a multi-layer separation structure, the principle is the same as above.

Technical Parameters

| parameters | Diameter /mm | Length /mm | Surface field /mt | Upper particle size /mm | Ore throughput | Weight | Power/kW |

|---|---|---|---|---|---|---|---|

| (t/h) | /t | Motor | |||||

| GTQ0105-Ⅰ | 100 | 500 | 1500 | 6 | 0.4~0.6 | 0.3 | 0.55×1 |

| GTQ0105-Ⅱ | 100 | 500 | 1500 | 6 | 0.4~0.6 | 0.7 | 0.55×2 |

| GTQ0110-Ⅰ | 100 | 1000 | 1500 | 6 | 0.7~3 | 0.6 | 1.1×1 |

| GTQ0110-Ⅱ | 100 | 1000 | 1500 | 6 | 0.7~3 | 1.3 | 1.1×2 |

| GTQ1510-Ⅰ | 150 | 1000 | 1500 | 12 | 1.5~4 | 0.8 | 1.5×1 |

| GTQ1510-Ⅱ | 150 | 1000 | 1500 | 12 | 1.5~4 | 1.7 | 1.5×2 |

| GTQ1515-Ⅰ | 150 | 1500 | 1500 | 12 | 2~10 | 1.1 | 1.5×1 |

| GTQ1515-Ⅱ | 150 | 1500 | 1500 | 12 | 2~10 | 2.3 | 1.5×2 |

| GTQ0310-Ⅰ | 300 | 1000 | 1500 | 30 | 8~30 | 1.4 | 2.2×1 |

| GTQ0310-Ⅱ | 300 | 1000 | 1500 | 30 | 8~30 | 2.9 | 2.2×2 |

| GTQ3510-Ⅰ | 350 | 1000 | 1500 | 30 | 15~45 | 1.6 | 2.2×1 |

| GTQ3510-Ⅱ | 350 | 1000 | 1500 | 30 | 15~45 | 3.3 | 2.2×2 |

| GTQ3515-Ⅰ | 350 | 1500 | 1500 | 30 | 25~60 | 1.8 | 2.2×1 |

| GTQ3515-Ⅱ | 350 | 1500 | 1500 | 30 | 25~60 | 4 | 2.2×2 |

| GTQ0410-Ⅰ | 400 | 1000 | 1500 | 40 | 20~50 | 1.4 | 3×1 |

| GTQ0410-Ⅱ | 400 | 1000 | 1500 | 40 | 20~50 | 2.9 | 3×2 |

| GTQ0415-Ⅰ | 400 | 1500 | 1500 | 40 | 30~65 | 2.1 | 3×1 |

| GTQ0415-Ⅱ | 400 | 1500 | 1500 | 40 | 30~65 | 4.3 | 3×2 |

| GTQ0418-Ⅰ | 400 | 1800 | 1500 | 40 | 35~80 | 2.2 | 3×1 |

| GTQ0418-Ⅱ | 400 | 1800 | 1500 | 40 | 35~80 | 4.5 | 3×2 |

| GTQ0610-Ⅰ | 600 | 1000 | 1500 | 50 | 25~60 | 2.3 | 3×1 |

| GTQ0610-Ⅱ | 600 | 1000 | 1500 | 50 | 25~60 | 4.7 | 3×2 |

| GTQ0615-Ⅰ | 600 | 1500 | 1500 | 50 | 35~75 | 3.2 | 3×1 |

| GTQ0615-Ⅱ | 600 | 1500 | 1500 | 50 | 35~75 | 6.5 | 3×2 |

| GTQ0810-Ⅰ | 800 | 1000 | 1500 | 60 | 25~55 | 3.1 | 3×1 |

| GTQ0810-Ⅱ | 800 | 1000 | 1500 | 60 | 25~55 | 6.4 | 3×2 |

| GTQ0815-Ⅰ | 800 | 1500 | 1500 | 50 | 35~70 | 3.9 | 4×1 |

| GTQ0815-Ⅱ | 800 | 1500 | 1500 | 50 | 35~70 | 7.9 | 4×2 |

Related Recommendations